In the rapidly evolving landscape of cannabis products, *THCA joint production* stands out as a fascinating area of innovation. Unlike traditional THC, *THCA* (tetrahydrocannabinolic acid) is a non-psychoactive compound found in raw cannabis plants. When exposed to heat, THCA converts to THC, the compound responsible for the ‘high’ associated with marijuana. This feature makes THCA joints a unique product, offering users a different spectrum of effects compared to standard THC products.

*THCA joints* are becoming increasingly popular due to their potential benefits, which include anti-inflammatory and neuroprotective properties. These joints provide a way for consumers to experience the therapeutic advantages of cannabis without the intense psychoactive effects. This has broadened the appeal of cannabis products to a wider audience, including those who seek medicinal benefits without the altered state of consciousness.

At *Smoke Show Labs*, we specialize in the production and co-packing of a variety of cannabis products, including THCA joints. With our extensive experience in Delta-8 (hemp) vape manufacturing, co-packing, and white labeling, we are well-equipped to assist you in bringing your THCA joint product to market. Let’s start your Delta-8 brand and explore the exciting possibilities of THCA joint production together.

Benefits of THCA Joints

One of the most compelling aspects of *THCA joints* is the array of *potential benefits* they offer. Unlike THC, THCA is non-psychoactive, meaning it does not produce the ‘high’ commonly associated with cannabis. This makes THCA joints an appealing option for individuals seeking the therapeutic benefits of cannabis without the psychoactive effects.

Studies have suggested that THCA may possess a variety of medicinal properties, including:

- Anti-inflammatory: THCA has been shown to reduce inflammation, making it potentially useful for conditions such as arthritis and other inflammatory diseases.

- Neuroprotective: Research indicates that THCA may help protect brain cells, which could be beneficial for neurodegenerative diseases like Alzheimer’s and Parkinson’s.

- Anti-emetic: THCA has been found to be effective in reducing nausea and vomiting, which can be particularly helpful for chemotherapy patients.

- Analgesic: The compound may offer pain-relieving properties, providing an alternative to traditional pain medications.

Moreover, the consumption of THCA joints allows users to benefit from the *entourage effect*, a phenomenon where different cannabinoids and terpenes work together to enhance each other’s effects. This synergy can lead to a more balanced and effective therapeutic experience.

As the interest in cannabis-based therapies continues to grow, THCA joints are emerging as a versatile and valuable addition to the market. Whether for recreational or medicinal use, these joints offer a unique way to harness the benefits of cannabis.

Understanding the Legalities of THCA

Navigating the legal landscape of *THCA* can be complex, given how cannabis laws vary significantly by jurisdiction. In the United States, the legality of THCA is largely influenced by federal and state regulations surrounding cannabis and its derivatives.

Federally, the 2018 Farm Bill legalized hemp and its derivatives, provided they contain less than 0.3% THC on a dry weight basis. Although THCA itself is non-psychoactive, it can convert to THC when exposed to heat. This conversion raises legal concerns, especially in states with strict regulations against THC.

At the state level, laws can vary widely:

- Legal States: In states where both medical and recreational cannabis are legal, THCA is generally considered legal and can be purchased without significant restrictions.

- Medical-Only States: In states with medical cannabis programs, THCA may be available to patients with qualifying conditions. However, access typically requires a medical cannabis card.

- Prohibited States: In states where all forms of cannabis are illegal, possessing or selling THCA products can result in legal penalties.

Internationally, the legal status of THCA varies. Some countries have progressive cannabis laws, allowing the use of THCA, while others maintain strict prohibitions against any cannabis-related compounds.

It’s crucial for consumers and businesses to stay informed about the latest regulations in their specific locales. Consulting with legal experts and staying updated on legislative changes can help ensure compliance and avoid potential legal issues.

Understanding the legalities surrounding THCA is essential for anyone involved in its production, sale, or consumption. By adhering to regulations, stakeholders can safely and effectively navigate the complexities of the cannabis industry.

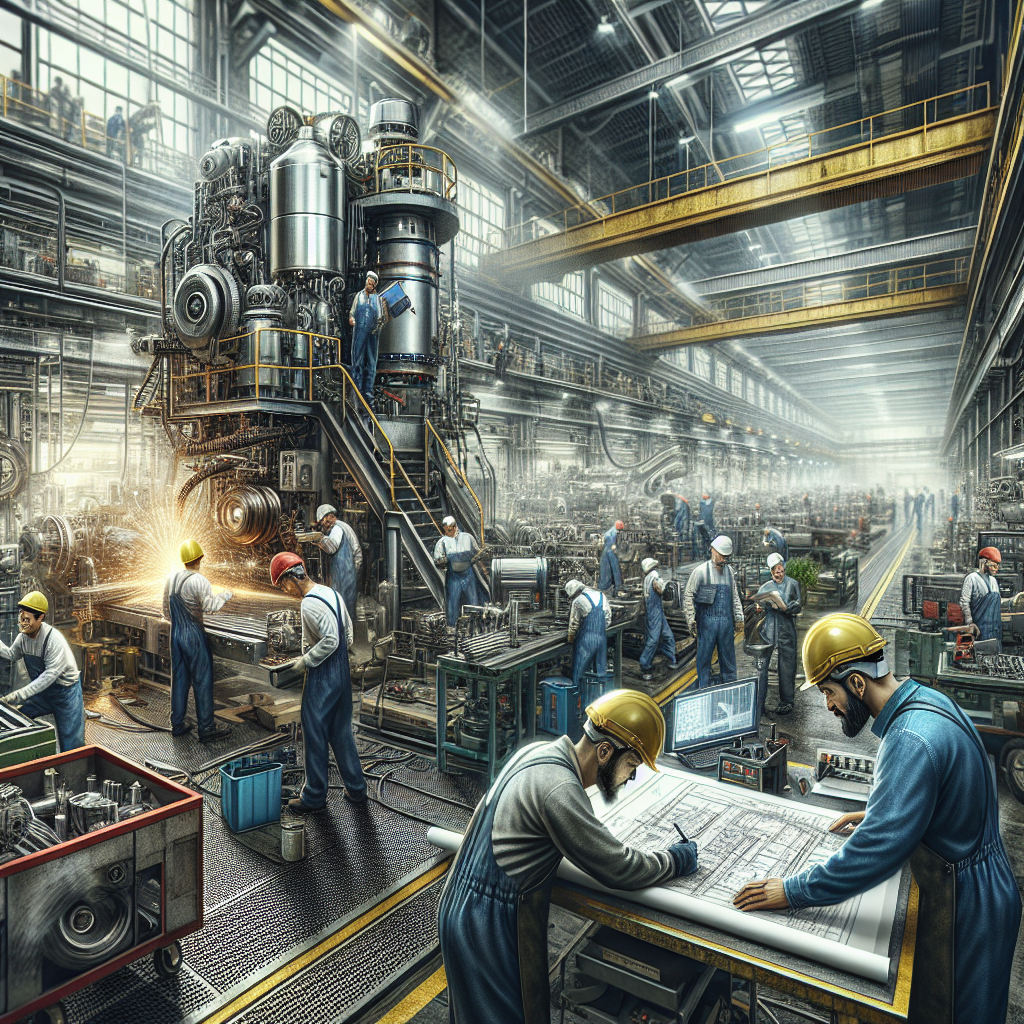

Step-by-Step Guide to THCA Joint Production

Producing *THCA joints* involves several meticulous steps to ensure quality and compliance. From selecting the right strain to packaging the final product, each phase requires attention to detail and adherence to industry standards.

Here is a step-by-step guide to THCA joint production:

- Strain Selection: Choose high-THCA strains that are well-suited for joint production. Strains rich in THCA can offer the desired effects and benefits, making them ideal for this purpose.

- Harvesting: Harvest the cannabis plants at their peak maturity to ensure maximum THCA content. Proper timing and methods are crucial to preserving the cannabinoid profile.

- Drying and Curing: Once harvested, the cannabis needs to be dried and cured correctly. This process involves hanging the buds in a controlled environment to remove moisture without degrading the THCA.

- Grinding: After curing, the cannabis buds are finely ground to achieve a consistent texture. This ensures an even burn and a smooth smoking experience.

- Rolling: The ground cannabis is then rolled into joints using pre-cut rolling papers. Precision and consistency are key during this step to maintain product quality.

- Testing: Each batch of THCA joints should be tested for cannabinoid content, potency, and contaminants. This ensures the product meets safety and quality standards.

- Packaging: Finally, the joints are packaged in airtight, child-resistant containers to maintain freshness and comply with legal requirements. Proper labeling with detailed product information is also essential.

Following these steps helps ensure that the THCA joints are of the highest quality, providing a premium experience to consumers. By adhering to industry best practices, producers can build trust and foster loyalty among their customer base.

Quality Control in THCA Joint Production

Maintaining quality control in THCA joint production is crucial to delivering a safe and premium product to consumers. Quality control encompasses various checks and balances throughout the production process to ensure consistency, safety, and compliance with regulatory standards.

Here are key aspects of quality control in THCA joint production:

- Source Verification: Ensure that the cannabis used is sourced from reputable growers who follow sustainable and ethical farming practices. This guarantees that the raw materials are free from harmful pesticides and chemicals.

- Laboratory Testing: Conduct comprehensive lab testing on the raw cannabis material as well as the final product. Tests should include cannabinoid potency, terpene profile, and screenings for contaminants such as mold, heavy metals, and pesticides.

- Standard Operating Procedures (SOPs): Implement and adhere to SOPs for every stage of production. These procedures help maintain consistency and reduce the risk of errors or contamination during the manufacturing process.

- Employee Training: Regularly train staff on best practices and safety protocols. Well-trained employees are better equipped to handle the intricacies of THCA joint production, ensuring a high-quality outcome.

- Batch Tracking: Use batch tracking systems to monitor the production process from start to finish. This allows for traceability and accountability, making it easier to identify and address any issues that may arise.

- Environmental Controls: Maintain a controlled environment for drying, curing, and storage. Factors such as humidity, temperature, and light exposure can significantly impact the quality of the final product.

- Final Inspection: Before packaging, conduct a final inspection of the THCA joints to check for uniformity in size, shape, and weight. Ensure that each joint meets the established quality standards.

By implementing rigorous quality control measures, producers can ensure that their THCA joints are safe, effective, and of the highest quality. This not only enhances consumer satisfaction but also helps build a reputable brand in the competitive cannabis market.

Future Trends in THCA Joint Production

The landscape of THCA joint production is constantly evolving, influenced by technological advancements, regulatory changes, and consumer preferences. As we look ahead, several key trends are likely to shape the future of this burgeoning industry.

One significant trend is the increased adoption of automation in the production process. Automation can enhance efficiency, reduce labor costs, and minimize human error, leading to more consistent and high-quality products. From automated trimming machines to advanced packaging systems, technology is set to revolutionize how THCA joints are produced.

Another promising trend is the focus on sustainability. As consumers become more environmentally conscious, there is a growing demand for eco-friendly practices in cannabis production. This includes the use of renewable energy sources, sustainable farming methods, and biodegradable packaging materials. Producers who prioritize sustainability will not only appeal to a broader audience but also contribute to a healthier planet.

Innovation in product differentiation is also on the rise. Companies are exploring new ways to stand out in a crowded market by offering unique formulations, such as terpene-infused joints or joints blended with other beneficial cannabinoids. These differentiated products cater to specific consumer needs and preferences, providing a competitive edge.

Lastly, the evolving regulatory landscape will continue to impact THCA joint production. As more states and countries move towards legalization, producers must stay informed and compliant with changing regulations. This includes adhering to quality standards, proper labeling, and ensuring product safety.

Embracing these future trends will be pivotal for companies looking to thrive in the competitive cannabis industry. If you are ready to elevate your Delta-8 brand and explore new opportunities in THCA joint production, let’s start your Delta-8 brand today!